Chocolate & Confectionery

The leading manufacturer in chocolate tempering, enrobing, cooling, decorating, bar making & confectionery forming. From the raw material to the final product, Sollich’s systems fulfil multifaceted and diverse production requirements.

If you require a price, a drawing, a spare part/service for existing equipment, or a solution to a problem, please call or contact us.

If you are making moulded or enrobed products from liquid chocolate, tempering machines form the core of a chocolate processing system. The pre-crystallisation of cocoa butter provides the foundation for all subsequent processes ensuring optimum shine, a long shelf-life, good snap and a heat-resistant product.

Since the invention of the SOLLICH Circulation Tempering Process over 60 years ago, there has been no more significant breakthrough in chocolate pre-crystallization than the Turbotemper®e.

The Turbotemper®e proves its exceptional tempering quality not only with pure cocoa butter chocolates, but also chocolates with a high percentage of milk fat or cocoa butter equivalents (CBE’s). Even pure cocoa butter can be successfully pre-crystallized. Available in throughputs from 100 kg/hr to 18,000 kg/hr and available in niche executions to suit specific duties, the characteristics and advantages are clear.

If you are making moulded or enrobed products from liquid chocolate, tempering machines form the core of a chocolate processing system. The pre-crystallisation of cocoa butter provides the foundation for all subsequent processes ensuring optimum shine, a long shelf-life, good snap and a heat-resistant product.

Since the invention of the SOLLICH Circulation Tempering Process over 60 years ago, there has been no more significant breakthrough in chocolate pre-crystallization than the Turbotemper®e.

The Turbotemper®e proves its exceptional tempering quality not only with pure cocoa butter chocolates, but also chocolates with a high percentage of milk fat or cocoa butter equivalents (CBE’s). Even pure cocoa butter can be successfully pre-crystallized. Available in throughputs from 100 kg/hr to 18,000 kg/hr and available in niche executions to suit specific duties, the characteristics and advantages are clear.

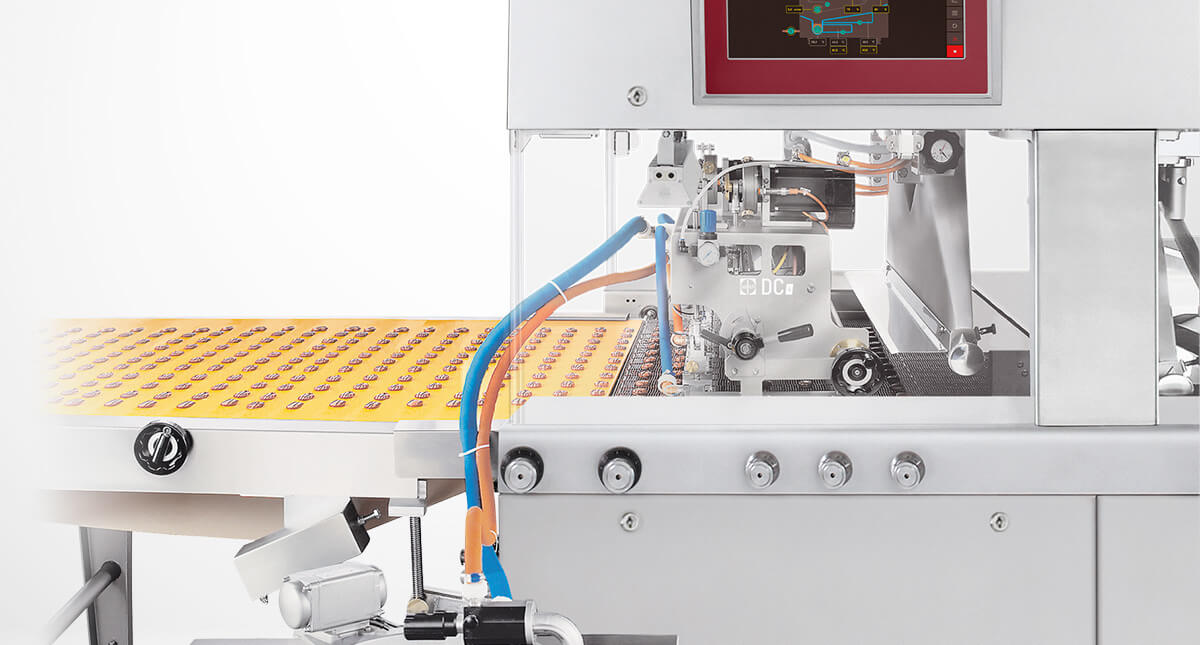

SOLLICH is the leading global manufacturer in this sector. Minicoater working widths available: 320mm and 420mm.

The MC 320 is fitted with a MinitemperR Turbo MT 100 tempering machine and the MC 420 is fitted with a MinitemperR Turbo Mt 150 tempering machine.

Minicoaters are equipped with all the main features associated with bigger enrobers so enrobing quality, accuracy and control are assured. The on-board temperer consistently gives you freshly tempered chocolate throughout a production run.

SOLLICH THERMO-FLOW universal, multi-zone cooling tunnels are manufactured in widths from 320mm up to 3,000mm and in lengths up to 100m. They are built modularly and designed to improve cooling efficiency and product quality. The patented temperature control system which adjusts the tunnel temperature according to the heat load ensures optimum energy efficiency and chocolate gloss.

With the different types of cooling tunnels LSK, KSK and KK, we can offer high duty tunnels for centre or slab cooling, cooling tunnels for chocolate coatings or for multiple applications.

The decoration is the face of your product. Sollich provides extensive options helping you to produce a distinctive and irresistible design. Among the various methods of product decoration, chocolate decoration is still the most common which is where the Sollich Decormatic® comes in.

There are four different versions of the SOLLICH Decormatic® available, each offering varying levels of speed, complexity and automation. Working widths: 320mm up to 1600mm

The Decormatic is installed inside an enrober, in between an enrober and a cooling tunnel or simply over a conveyor. It can operate as a standalone machine or in combination with a Trailing Wire Device to give a feathered pattern and it’s usually supplied with tempered chocolate from a SOLLICH Minitemper Turbo.

Sollich’s product portfolio offers the right solution for a wide variety of confectionery bars, from cereal bars to protein bars, from raw materials to finished products.

SOLLICH has manufactured over 500 bespoke Conbar Bar Lines over the last 30 years to handle throughputs of 100kg to 5000kg/hour over working widths of from 300mm to 1300mm.

Conbar lines are tailor made, flexible, reliable, easy to operate and easy to clean.

The Chocotech Candy Division, a subsidiary of SOLLICH, will design and manufacture a batch or continuous kitchen to produce the binder or mass required on the Conbar line.

Bar Types: Candy Bars, Cereal Bars, Brittle Bars, Fruit Bars, Protein Bars.

Need help with spare parts or is it time to book a service?

Our experienced team are available to help if you need a price, a drawing, a solution to a problem or a spare part / service for your existing equipment.

Please call us on +44 (0) 1780 784007 or complete our request form.

Over 25 years we have created lasting partnerships with our customers, here are some of their comments.

Keep up with all the latest news from Sollich and the chocolate, confectionery and baked goods industries.

Posted: December, 2025

Thank you for your continued support and your business throughout 2025. We wish you and your loved ones a very happy, healthy, and prosperous 2026.

©2022 Sollich UK Ltd. All Rights Reserved | Made by JKE Web Design